Reintroducing Micropiling Technology to the Philippine Construction Industry as an Effective Alternative to Preserving Historical Buildings and Superstructures.

One of the areas of expertise of TREVI, a BluPrint source, is the Micropiling Technology. The use of micropiles in underground engineering has increased considerably thanks to the versatility of the technology and the possibility of using less heavy equipment, resulting in reduced impact on existing soil and superstructures.

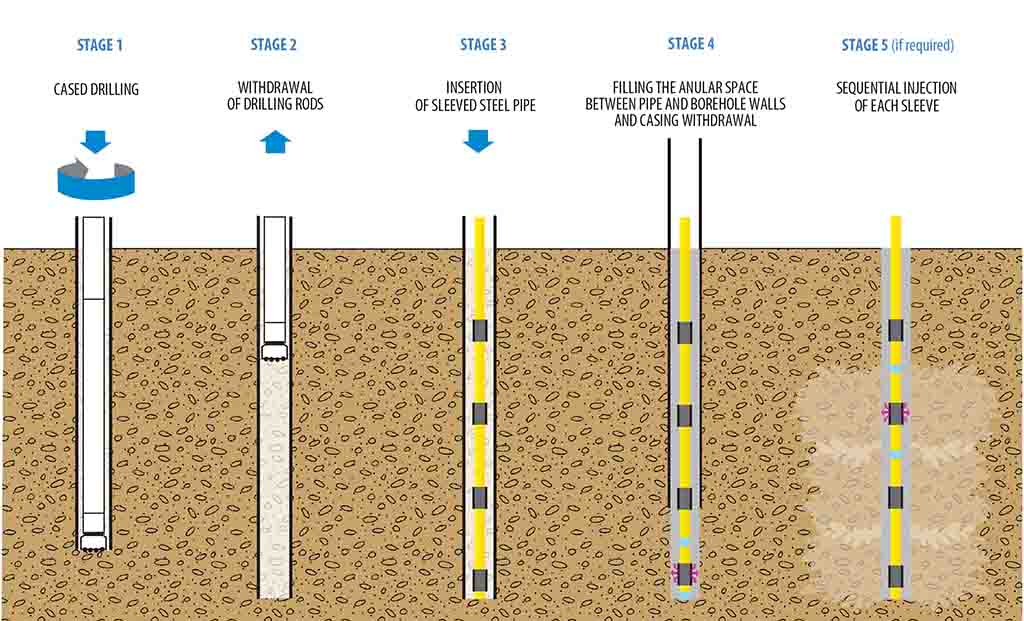

Micropiles are more recently defined as “a small diameter (less than 300mm), replacement, drilled pile composed of placed or injected grout, and having some form of steel reinforcement to resist a high proportion of the design load” (D.A. Bruce, 1999). The diameters of present-day micropiles range from 100-300mm, while the average depth is 30-35m. However, maximum depths can exceed 100m. Dr. Fernando Lizzi (1914-2003), registered the patent for “root piles,” small diameter piles for underpinning of buildings subject to excessive settlement. The Micropiling Process may be explained more effectively through the following illustration.

In brief, the main benefits of this game-changing technology are the following: high load capacity both for tension and compression, ease of socketing into hard rock, simple construction set-up interface, and minimal disturbance to the surrounding environment during installation. When budget and resources permit it, Micropiling can be a good solution to underpin or retrofit the foundations of old structures. This is something that heritage councils and construction companies can explore further when addressing a structure’s cultural value and level of risk.

Some of the early examples that made use of this technology is the underpinning of historic buildings like Ponte Vecchio in Florence in 1966 and stabilizing the leaning tower in Burano. In reference with the long historical background of Philippine Architecture and Construction, heritage buildings run great risks of failure due to their vulnerable state and excessive settlement. Hence, the local industry ought to find solutions that will preserve and ensure their safety and serviceability.

Moreover, historical buildings show the Filipino People’s culture passed on across several generations. They serve as proof of the country’s resilience and a reflection of its own identity. It is only appropriate that we take an immense amount of effort to preserve them.

About the TREVI Group

Trevi Group is an Italian company founded by Davide Trevisani in 1957. The Trevi Group is a world leader in the field of underground engineering from special foundations, soil consolidation, and recovery of polluted sites, and in the design and marketing of specialized technologies in the sector.

The main reasons behind the success of the group is internationalization and integration – continuously exchanging information between their two divisions.

- Soilmec designs, manufactures and markets machinery, systems and services for underground engineering.

- TREVI carries out special foundations and soil consolidation works for large infrastructure projects like subways, dams, ports and docks, bridges, railway and highway lines, industrial and civil buildings, secures polluted sites, builds and manages underground and automated car parks.

TREVI operates in the execution of specialized works in the field of underground engineering, always obtaining excellent results, and it supplies services with high added value and with high profitability margins. Today, TREVI extends its services to Philippine Construction as it embarks on an ongoing Micropiling Project for JG Summit in Batangas City.