PH specialty paper Pinyapel bags a Wood Pencil at the D&AD Future Impact Awards

Global non-profit advertising and design association organization Design and Art Direction (D&AD) recognizes the potential of Pinyapel, a Philippine-made specialty paper made from discarded pineapple leaves, in creating a significant impact on the environment and sustainability as a food packaging alternative to single-use plastic. The Pinyapel research and development team will receive a Wood Pencil (industry professionals consider the D&AD pencil as equivalent to “career knighthood”) at the D&AD Future Impact Awards 2019 in New York City, USA, on November 6.

Pinyapel was the result of a research and development initiative led by the Design Center of the Philippines (DCP) on agricultural waste and pineapple leaves. After its breakthrough research on developing the material, DCP collaborated with Nature’s Fresh Pineapples for the supply of raw materials, CDO Handmade Paper for paper sheet processing, and Ideatechs Packaging, Inc. for paper sheet conversion to food packaging applications.

Opportunities unfold

Based in the United Kingdom, D&AD “stimulates, enables and awards creative excellence in design and advertising” worldwide. The organization also holds world-class training programs, accelerator platform, and festival to support the industry towards creative excellence. Hence, the Pinyapel team will also receive a place on the D&AD Future Impact Accelerator program, which will help accelerate Pinyapel’s development to deliver a tangible impact in their category area within 12 months.

Winning a Wood Pencil also provides an opportunity for the Pinyapel team to pitch at the D&AD Festival 2020 to gain support from venture capitalists (VCs) and creatives. It also grants the team a pass to the D&AD Festival 2020, a dedicated space at the Impact exhibition in London, a 12-month membership, and a year of exposure to a global audience through D&AD and third-party press.

READ MORE: Good Design Award Philippines recognizes impact-driven design solutions

Before the Wood Pencil

The Design Center’s materials research and development program has explored the potential of agricultural waste and otherwise overlooked resources as raw materials for various product applications, impacting the design and value of Philippine products. The Pinyapel project aims to produce sustainable, cost-effective, and commercially viable materials and contribute to strengthening local businesses.

With the challenges faced by the pulp and paper industry in sourcing pulp locally, DCP’s move to develop Pinyapel and partner with local businesses provided an alternative and sustainable source for paper. It is also seen as an additional income source for farmers in the country’s large pineapple production area, with a total of 63,904 hectares, according to the Philippine Statistics Authority’s April -June 2019 Quarterly Bulletin on Major Fruit Crops. Thus, providing new purpose and value to what was previously considered agricultural waste.

“The project began with the intent of maximizing the use of agricultural waste to improve the livelihood of farmers, address concerns on dwindling natural resources and offer alternatives to plastic, collaborate with local enterprises, and show the world what the creative and design mind of Philippines can do,” said DCP Executive Director Rhea O. Matute. “With the country’s desire for a more value-creating economy, the Design Center hopes to develop and unlock more commercialization opportunities for impactful ideas like Pinyapel.”

READ MORE: Four Filipino Firms Make World Architecture Festival 2019 Awards Shortlist

Pinyapel production and use

Pinyapel is a specialty paper reinforced and print-viable for secondary packaging applications such as gift bags, paper cup sleeves, and corrugated paper.

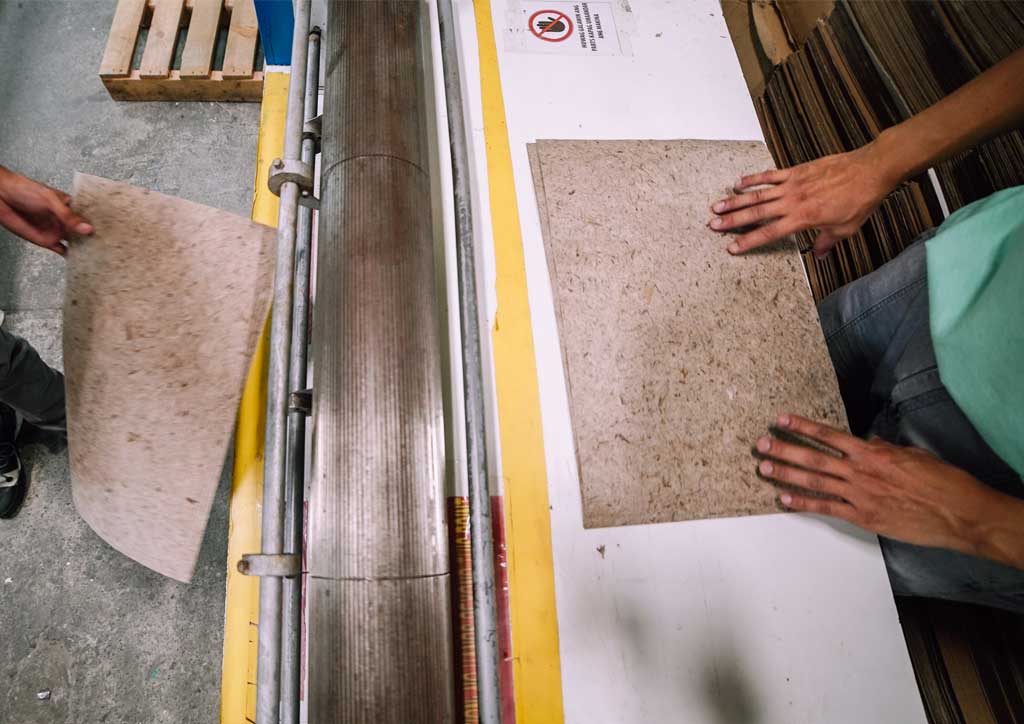

The production involves harvesting the discarded leaves from pineapple plantation, drying the leaves under direct sunlight, pulping and rinsing the cut leaves, and pounding the cleaned pulp. Reinforcing solutions are used to improve the mechanical properties of the material. Once dry, the paper sheets are either run in corrugating machines for corrugated paper and cup sleeves or cut out for paper bag production.

Pinyapel leaves during production and after consumer use can be used as raw materials to produce brown bags and cardboards.