LOOK: UP architects design a COVID-19 testing vehicle

Netizens have long been pushing for the conduction of a mass testing, with numerous posts and tweets leading the hashtag #MassTestingNow to trend. With the country holding a record number of 5,223 confirmed cases, 335 deaths, and 295 recoveries as of 4:00 PM today, April 14, 2020, efforts to flatten the curve call for faster and more efficient solutions.

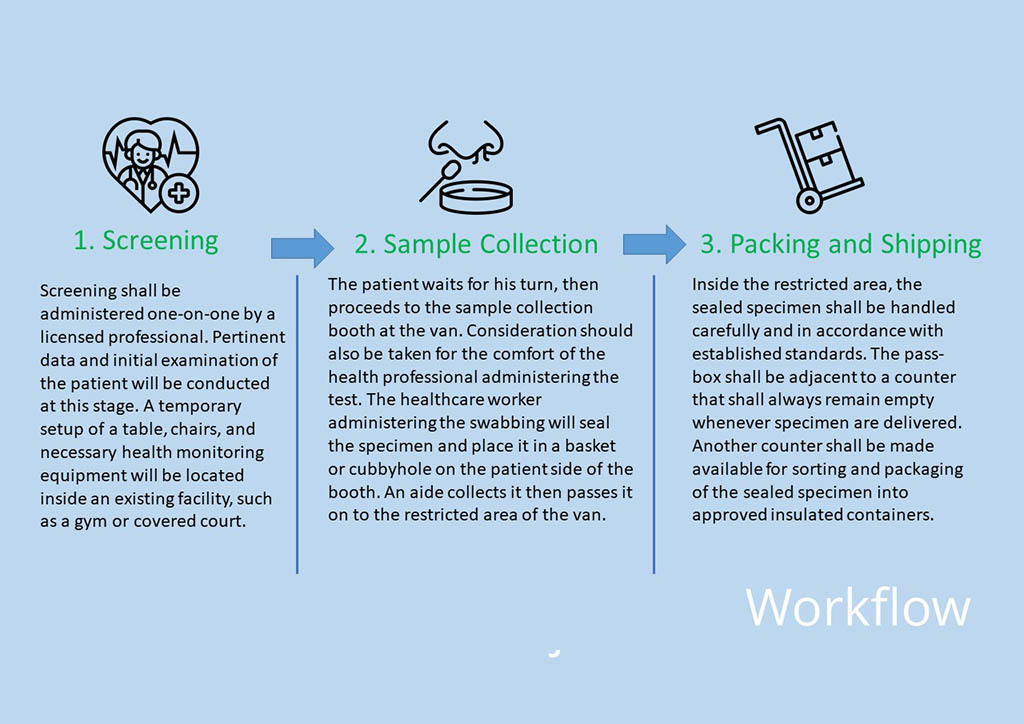

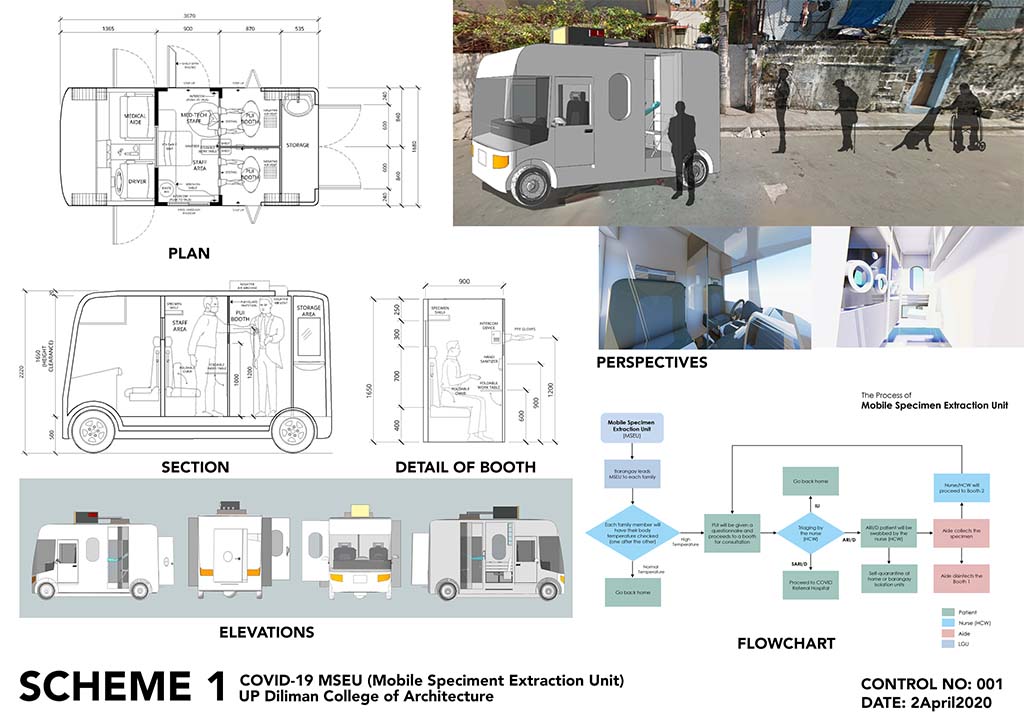

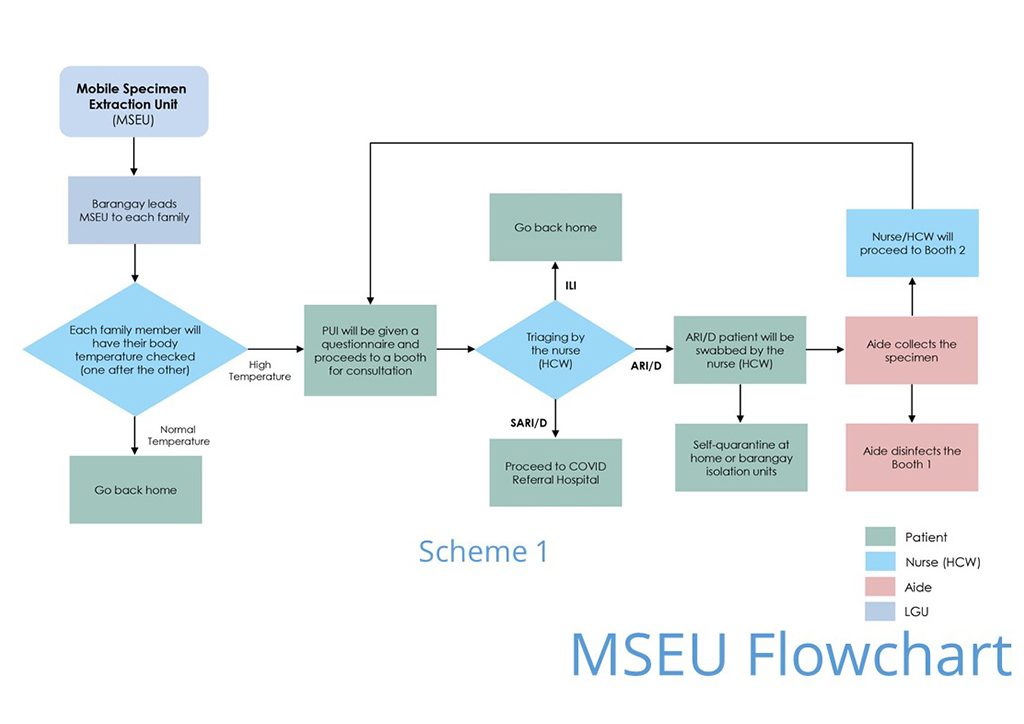

The conversion of buildings has grown, with PICC, Ninoy Basketball Stadium, selected New Clark City facilities, and other public spaces now transformed into quarantine centers. Several architecture firms have also proposed tent designs and layouts of isolation facilities. As part of their contribution to the clamor for mass testing, architects from the University of the Philippines Diliman College of Architecture raised their voices by crafting a layout for their Mobile Specimen Extraction Unit. The testing vehicle designed to collect specimen from patients with ILI (Influenza-like Infections), patients with ARI/D (Acute Respiratory Illnesses with Diarrhea), those who have had contact with COVID-19 positive patients, and all who have been previously identified by the barangays was first introduced by the team through a Facebook post last April 2, 2020.

The driving force

“One day, during the lockdown, we thought of collating all our concerns, and just one week after we had our first online meeting and delegated tasks, we already came up with designs for a prototype,” recalls the group. Prior to their first online meeting, the group read about the concerns of keeping front liners safe and making health facilities and testing centers more accessible to all. “That’s where the idea came to us. We thought that it’s possible to come up with a solution that can reach out to more people who need to be tested and at the same time protect our healthcare workers.”

Nicknamed the ‘COVID Catcher’, the idea of having the Mobile Specimen Extraction Unit is to decongest testing centers. Having a testing vehicle which will collect swab samples from barangays will save an ample amount of energy, time, and space. Moreover, it will enable healthcare workers in laboratories to focus on testing, which is a crucial process especially during this time of crisis. “Our country doesn’t have a lot of healthcare workers who are trained to conduct COVID-19 tests, but we can more readily tap more workers to do the specimen collection,” says the team. “Instead of making possibly infected individuals from far-flung areas travel all the way to the testing centers, the mobile unit will go to them.” The group shares that their crafted prototype is based on the Smartbus model of Japanese electric vehicle development and business process reform company Assemblepoint.

Steering the wheel

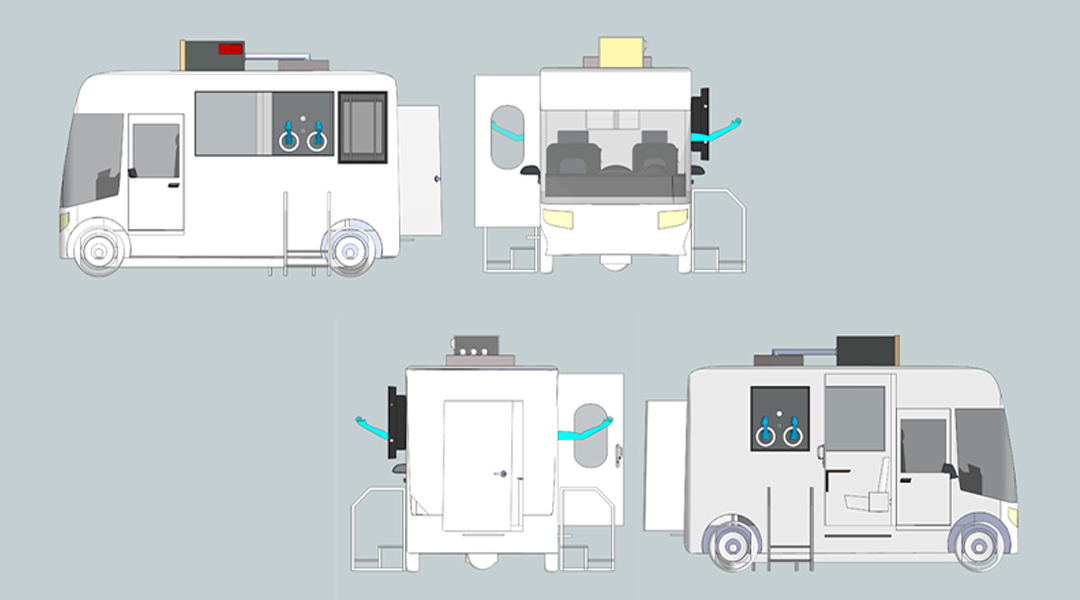

One of the primary considerations made by the team is that the materials used should be “easy to clean and will inhibit the growth of microorganisms.” The first layout designed by the architects features four compartments that illustrate both the form and function of the testing vehicle. The four compartments namely the driver’s compartment, restricted compartment (medical staff area), patient’s compartment (PUI booth), and storage compartment focus on the safety and stability of the structure and the safe performance of the specimen collection. Between the medical staff area and the PUI booth is a plexiglass partition, which is often used as a shatter-resistant alternative to glass and is wipe down clean. A negative air machine is placed into the PUI booth, preventing possibly contaminated air from escaping the room.

When asked how long and how many people will it take to set up one MSEU, the team responded that it “depends on the vehicle that will be used.” According to them, if only minimal modifications are needed and if enough people will be cleared to work, one MSCU can be set up in a week. “We can also customize depending on the vehicle type. What is important is that the interior has enough headroom to allow our healthcare workers to stand up and walk comfortably.” For redundancy, UV lights will be used within the ducts of the entire structure. The group also suggests that an intercom be added for better communication between the healthcare worker and the patient.

Taking the high road

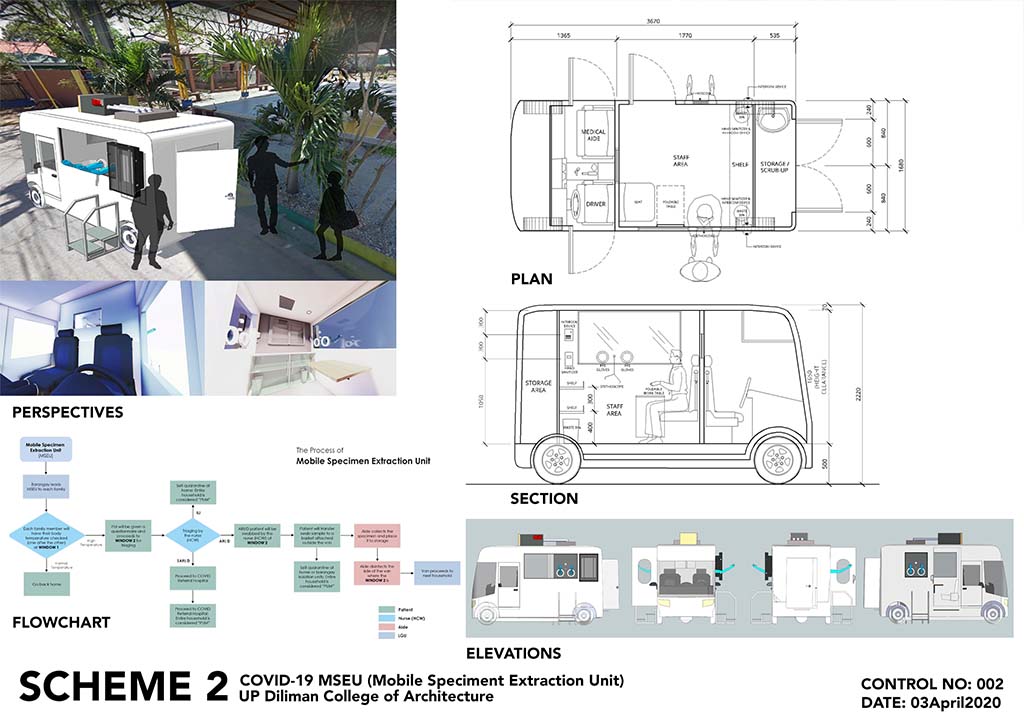

“Shortly after we shared our output online, the government announced its plan to conduct mass testing nationwide,” the team narrates. What started as an initiative eventually became a talked-about project, with their Facebook post reaching more than 2,000 reactions and shares, along with a hundred comments. “Since then, we have been hearing inputs and feedback from all sorts of people, and they have been helping us refine or customize the designs even further.”

Inputs and feedbacks led the group to create a second layout. For this scheme, the patients or PUIs are situated outside the testing vehicle. “The mobile unit will be parked in a central location beside or inside a big facility like a gymnasium, where it will be connected to water and electricity, and where patients and/or PUIs can be scheduled, processed, screened and queued at the right distance from each other.” The second layout only holds three compartments, giving the medical staff area more space as compared to the first scheme. Given that any surface that comes in contact with the patient is sanitized after every swab test, this second scheme implies that only a few surfaces will need sanitation every now and then. In both schemes 1 and 2, the medical staff or restricted area is protected, not needing sanitation after every specimen collection.

Pondering on the effects of the COVID-19 outbreak, the team says that “the need for chemical, biological, radiological, and nuclear preparedness is a field of study which the industry and our people should not take for granted.” Currently, the group is seeking the approval of their testing vehicle prototype. They are hoping that this endeavor will also reach the right people in order to implement it successfully. “At the end of the day, our end users, which include both patients and healthcare workers, should have an environment that promotes wellness and healing.”

Project team

Architects

Erwin Albis

Ronald John Dalmacio

Cristopher Espina

Feng Ambrosio Gascon

John Ernest Jose

Dorothy Lee

Maria Victoria Perez-Mallare

Mariethel Garing-Matabang

Rinary Paca

Richard Martin Rinen

Miguel Andres Salcedo

Biosafety Officer

Bianca Adalem

Consulting Doctor

Emer Jose

READ MORE: 10 Things to observe for PUI and PUM COVID-19 quarantine hospitals